The Unsung Heroes in the Frontline - Contributing to the Resumed Operations in Shanghai

As the Covid situation improved, the Shanghai Government immediately began approving enterprises to resume production in late April. Thanks to the tireless efforts made by our employees around the clock, production in Volvo CE, Volvo Penta and GTO China have been successively restarted.

|

In Volvo CE Shanghai plant, Bin Jia, the Senior Administration Specialist, started his busy work even before the approval was granted for the plant to resume production in early May. As a member of the Crisis Management team responsible for planning and implementing Covid prevention and production resumption, he spent days and nights working out the details of the plan with colleagues. As a result, the thoroughness of the plan placed Volvo CE plant on the 2nd batch of enterprises to restart production. Then Bin immediately engaged in new tasks. His daily schedule was tight, including preparing all the health documents and listing the different batches of returning employees, arranging the living area and 3 meals, securing procurement of essential supplies despite the logistic restrictions, etc.

One morning in mid-May, Bin received a notice that the supplier could not deliver the breakfast and lunch to the plant due to unexpected road closures in Pudong New Area, which entered a one-week "silent period". Thanks to the critical backup food Bin prepared, the breakfast was made available to all staff. And after solving the breakfast problem, Bin immediately contacted the backup supplier with the qualifications to deliver the lunch to the plant on time. The early contingency plans that Bin and his team made proved critical in the time of urgency.

|

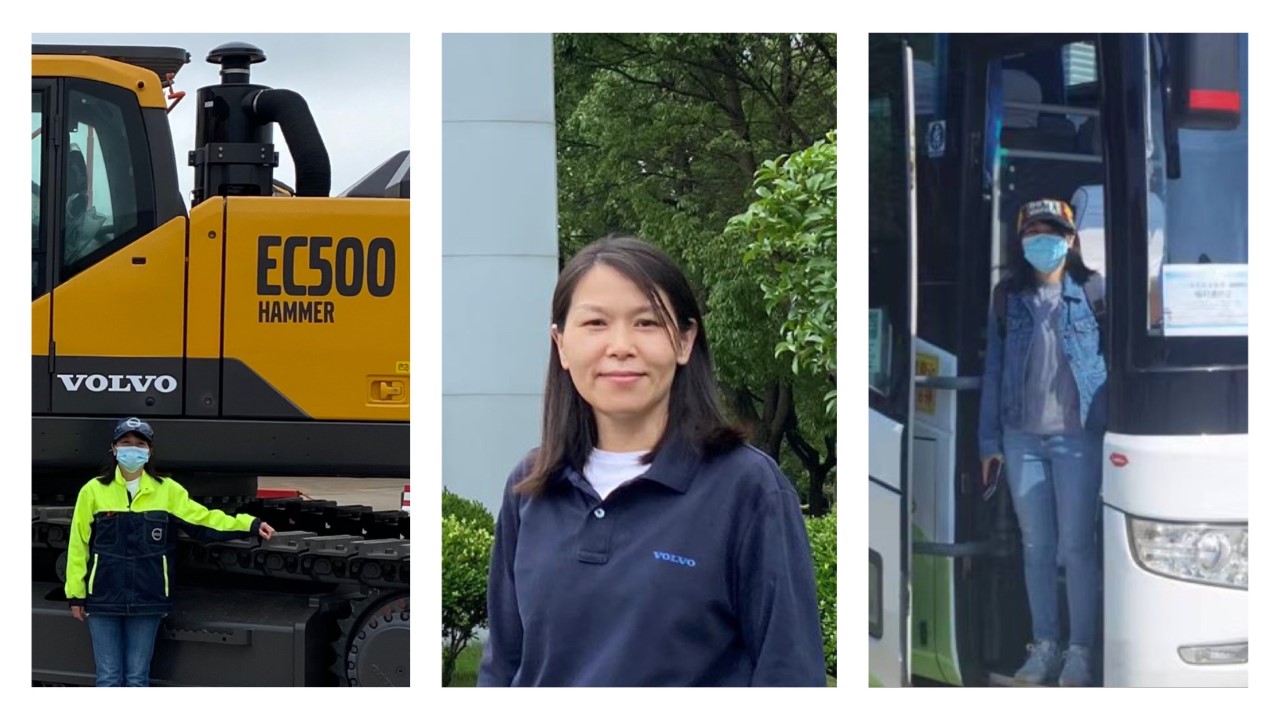

In line with the plan, a total of 110 employees of 5 different batches eventually returned to the Volvo CE Shanghai plant and worked in the closed loop. Among them is Ziyi Mei, the Quality Planning Manager of Volvo CE Shanghai plant, who returned in the first batch on May 5. She deployed her quality improvement expertise to every aspect of the work assigned to her, ensuring the production and life in the closed loop went as orderly as planned. For example, she used Wechat as a communication tool across different functions to improve communication efficiency; she distributed questionnaires online to collect the opinions and suggestions from employees concerning the quality of meals and responded swiftly, etc.

On top of that, Ziyi was mainly responsible for organizing after-work activities for the 100+ employees, including lawn birthday parties, movie nights, and outdoor workout sessions. She also put on various fun activities, such as push-up challenges, ringtoss competitions, etc, injecting more fun factors into the otherwise stressful time in the closed loop. What’s more, Ziyi regularly went to the staff dormitory to chat with everyone after work, asking about their sleep quality, psychological state and other needs, making their lives in the closed loop less stressful and more home-like.

|

Similar stories were happening at Volvo Penta Lingang site. Huihua Pan, team leader of Material Handler in Warehouse Operations, also dedicated himself to resuming production. The preparation went underway in Penta as early as April 20 following the Shanghai Municipal Guidelines for the Resumption of Work and Production, including the preparation of daily life necessity supplies and Covid prevention materials. On May 5, the production of 7 engines was completed on the first day of resumption. On May 8, the plant received the first customer pick-up after closed-loop production began.

The workload Huihua took on himself contained 3 parts: preparing the required production materials for each day, receiving engines and production materials sent to the plant from ports/airports/bonded warehouses, as well as sorting and placing them on the warehouse shelves. Given the shortage of transportation resources, Huihua tried to coordinate all possible vehicles and smooth out the entire process. However, after the delivery arrived in large bulk, another issue arose - insufficient space for the engines and materials to be stacked. Huihua instantly came in with some solutions, including transferring the produced engines to the bonded warehouse and some parts to outdoor storage after being carefully packaged and protected, adjusting the storage of parts on the shelves to free up storage space, etc. Furthermore, Huihua received the online training to become a volunteer Covid PCR (Polymerase Chain Reaction) test sampler. He has passed the exam!

|

Like Huihua, Xiaoming Ma, Manager of Warehouse Operations & Support, SML China of GTO China in Shanghai Waigaoqiao site, was also committed to the work of logistics, a key link to support the business as usual. The operation of GTO China was restarted on May 8 with the efforts of all the personnel. While ensuring the regular operation of the company, Xiaoming and his team worked relentlessly to finish transporting 566 pieces of air transport parts stranded between March 28 and May 8, 20 of the 28 containers stranded in the sea, and over 9,000 out of 10,000 stranded orders. This helped normalize the work progress and alleviate the customers' concerns while waiting in agony.

When the plant was in closed-loop production, Xiaoming was most concerned with the psychological health of employees. To strive for a balance of production safety and work efficiency, he frequently communicated with relevant departments and implemented some solutions, such as increasing and diversifying the supply of living materials, adjusting operation types and workload of each employee in time, enriching employee leisure activities after work, and communicating more frequently with employees about their lives and concerns, etc.

Bin Jia, Ziyi Mei, Huihua Pan, and Xiaoming Ma have played a key part and made outstanding contributions to the resumption of production and work of Volvo Group in Shanghai during the Covid lockdown. They worked to the utmost to overcome various difficulties, exemplifying the values of Volvo Group: Passion, Change, Customer Success, and Performance. What they have gained through overcoming the challenges will also become valuable work experience and a driver for continuous self-growth.